Choosing the Right Peristaltic Pump for Your Lab: A Comprehensive Guide

- April 30, 2025

- ENQUIRE NOW

Choosing the Right Peristaltic Pump for Your Lab: A Comprehensive Guide

When it comes to precision fluid handling in laboratories, peristaltic pumps are an essential tool. From transferring sensitive biological samples to dispensing reagents and chemicals with accuracy, the right peristaltic pump can greatly enhance your lab’s workflow and data integrity. But with so many options available, how do you choose the right one?

In this blog, we’ll walk you through the key considerations for selecting a peristaltic pump tailored to your lab’s needs and discuss how different pump features can influence performance, reliability and overall user experience.

What is a Peristaltic Pump?

A peristaltic pump is a type of positive displacement pump that uses rollers or shoes to compress and release a flexible tube, moving fluid through the tube in a wave-like motion. This mechanism ensures that the fluid only contacts the tubing, minimizing the risk of contamination—a critical factor in biomedical, pharmaceutical, and chemical applications.

Why Peristaltic Pumps?

Peristaltic pumps are favored for several reasons:

- Non-contaminating flow path: Only the tubing contacts the fluid.

- High precision: Ideal for dosing and volume-sensitive tasks.

- Easy maintenance: Tubing replacement is straightforward and cost-effective.

- Reversible flow: Many models allow fluid to be pumped in both directions.

- Self-priming and dry running capabilities

These attributes make peristaltic pumps ideal for applications such as cell culture media transfer, reagent addition, buffer delivery, and waste disposal.

Factors to Consider When Choosing a Peristaltic Pump

- Application Requirements

Start with your application. Are you transferring liquids, dosing reagents, or sampling biological materials? Each use case may require different levels of flow rate, precision, and tubing compatibility.

- Low flow rates are critical for precise dosing in analytical or biotech labs.

- Higher flow rates may be needed for bulk transfer or filtration applications.

- Flow Rate Range

Determine the volume of liquid you need to pump and how fast. Choose a pump with a flow rate range that accommodates your current needs while offering flexibility for future applications. Typical lab applications range from microliters per minute to several liters per minute.

Determine the volume of liquid you need to pump and how fast. Choose a pump with a flow rate range that accommodates your current needs while offering flexibility for future applications. Typical lab applications range from microliters per minute to several liters per minute.

- Control Type

- Manual control is suitable for basic, low-precision applications.

- Digital control offers better accuracy and repeatability.

- Programmable models allow for complex dispensing cycles, timed intervals, or integration into automated systems.

Advanced pumps may also feature touchscreens, memory storage, and connectivity (USB, RS-485, Wi-Fi) for enhanced lab integration.

- Number of Channels

Multi-channel peristaltic pumps allow simultaneous pumping through multiple tubes. This is helpful in high-throughput environments or when working with multi-step protocols.

- Tubing Compatibility

Different peristaltic pumps are compatible with different tubing sizes and materials (e.g., silicone, PVC, or fluoropolymer). The tubing choice will affect:

Different peristaltic pumps are compatible with different tubing sizes and materials (e.g., silicone, PVC, or fluoropolymer). The tubing choice will affect:

- Chemical compatibility

- Sterility

- Pressure rating

- Flow rate accuracy

Always verify that the tubing supports the chemical and physical properties of the fluids you’ll be handling.

- Pump Head Design

The pump head determines how the tubing is compressed. Options include single-roller or multi-roller heads, which affect the smoothness of flow, pressure capabilities, and tubing wear.

- Cleanability and Maintenance

Pumps used in sensitive applications (e.g., biotech or food labs) must be easy to clean and sterilize. Tool-free tube changes and autoclavable parts are valuable features.

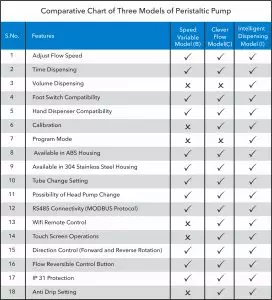

Microlit Peristaltic Pump Series: A Comparative Snapshot

Microlit, a trusted name in liquid handling, offers three series of peristaltic pumps tailored to different lab requirements: B-Series, C-Series and I-Series. Here’s a closer look at features that set Microlit’s new Peristaltic Pump range apart:

- Precision Flow Control: Achieve exceptional accuracy and consistent fluid flow across various viscosities

- Contamination Free Transfer: Ensures fluid contacts only with tubing, no contamination risk

- Durability and Efficiency: Minimal wear and tear due to its simple construction

- Customizable Tubing Compatibility: Enables fast tube changes, reducing downtime

- Compact and Easy to Use: Streamlined space-saving

design allows for easy installation in tight spaces - Versatile Applications: Ideal for chemical processing, pharmaceuticals and laboratory tasks amongst others

- Intuitive Interface: Offering enhanced convenience for both beginners and experienced operators

- ABS Engineering Plastic and Stainless Steel Housing: Both aesthetically pleasing and functional

The Intelligent models are the most advanced in the lineup, featuring intelligent control and capabilities suited for automated labs and demanding pharmaceutical or biotech environments.

The Intelligent models are the most advanced in the lineup, featuring intelligent control and capabilities suited for automated labs and demanding pharmaceutical or biotech environments.

Choosing the right peristaltic pump isn’t about finding the most powerful or feature-rich option—it’s about aligning pump capabilities with your specific lab needs. By understanding the nature of your application, flow requirements and desired control features, you can narrow down the options effectively.

Microlit’s peristaltic pump series cater to a spectrum of laboratory use cases, from simple media transfer to sophisticated automated dosing systems. Whether you’re a startup lab or a high-throughput biotech facility, there’s a Microlit solution built for your workflow.

To know more, email us at info@microlit.com or visit us at https://www.microlit.com/product-category/peristaltic-pump/