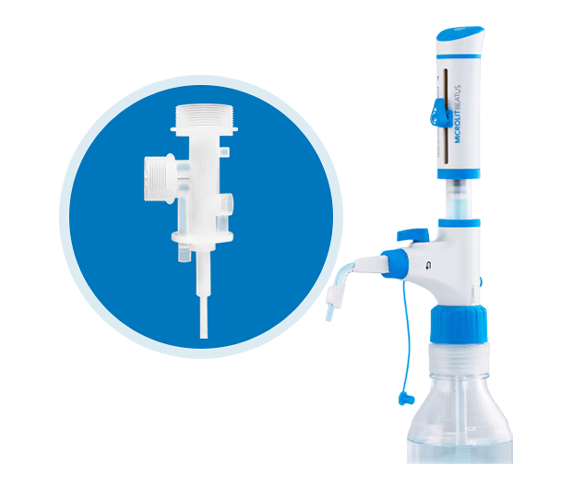

Springless Valve®

Traditional Bottle Top Dispensers contain two valves with glass balls.

Inlet Valve: This valve is vertical. It operates under gravity and does not require a spring to hold the glass ball in its position, in order to keep the valve closed.

Outlet Valve: This valve is horizontal. It requires a spring to keep the glass ball in its position, in order to keep the valve closed while aspirating reagents in the barrel. It opens only when a reagent is being dispensed.

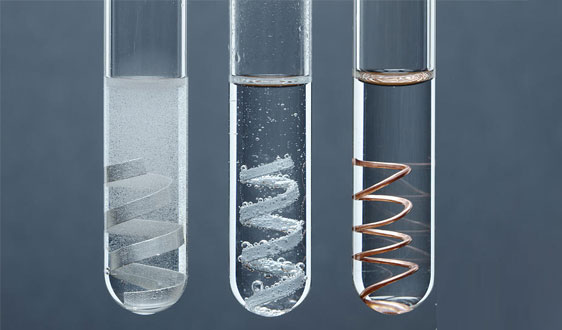

Spring Metal Reactivity

Depending on the application, the spring in the outlet valve is either made of Platinum Iridium or Tantalum. Platinum Iridium is not suitable for Hydrogen Peroxide whereas Tantalum has limitations with Sodium Hydroxide. Because of this spring metal reactivity, the user has to procure different kinds of Bottle Top Dispensers for different applications which just adds confusion and proves to be an expensive proposition.

Chemical Deposition

The spring also offers a surface for deposition of chemicals. This results in a piston jam, thereby compelling the user to repeatedly clean the valve, or replace it altogether.

MICROLIT’S Expert Technology Solution – Springless Valve ®

This Springless Valve TM Technology makes our Bottle Top Dispensers, Universal Bottle Top Dispensers that can be conveniently used with both organic and inorganic reagents. It not only ensures a service-free operation but also minimizes the total effort required to operate the instrument’s piston..