Best Practices for Using Microplates and Sealing Films in qPCR and PCR Experiments

- May 17, 2024

- ENQUIRE NOW

In the realm of molecular biology, precise and reliable results are paramount, especially in quantitative PCR (qPCR) and PCR experiments. The choice and handling of microplates and sealing films can significantly impact the quality and reproducibility of your data. Here, we delve into the best practices for using microplates and sealing films to ensure optimal performance in qPCR and PCR experiments.

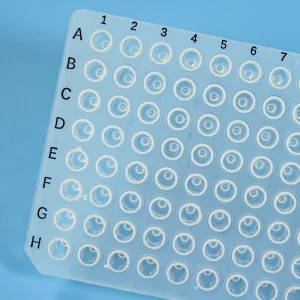

Understanding Microplates and Their Types

Microplates, also known as microtiter plates, are flat plates with multiple wells used as small test tubes. They come in various formats (24-well, 48-well, 96-well, 384-well, and 1536-well), with the 96-well format being the most commonly used in PCR and qPCR.

Key Considerations for Selecting Microplates

Material: Microplates are typically made from polystyrene, polypropylene, or polycarbonate. Polystyrene is widely used for its optical clarity, essential for fluorescence-based qPCR assays. Polypropylene offers better chemical resistance, making it suitable for reactions involving harsh chemicals.

Material: Microplates are typically made from polystyrene, polypropylene, or polycarbonate. Polystyrene is widely used for its optical clarity, essential for fluorescence-based qPCR assays. Polypropylene offers better chemical resistance, making it suitable for reactions involving harsh chemicals.

Well Shape: The well shape (flat, round, or V-bottom) can influence reaction efficiency and sample retrieval. Flat-bottom wells are preferred for optical measurements, while V-bottom wells are better for complete sample recovery.

Color: Clear microplates are ideal for optical assays, while white plates enhance signal reflection in luminescence-based assays. Black plates are used to minimize background noise in fluorescence assays.

Skirted vs. Non-Skirted: Skirted plates provide better rigidity and are compatible with automated handling systems, while non-skirted plates are more flexible and can fit into a wider range of thermocyclers.

Proper Handling of Microplates

To ensure accurate results, handling microplates correctly is crucial:

Avoid Contamination: Always wear gloves and use pipette tips with filters to prevent contamination. Work in a clean, controlled environment.

Consistent Pipetting: Use calibrated pipettes and maintain consistent pipetting techniques to ensure uniform sample volumes across all wells. This consistency is vital for reproducibility in qPCR experiments.

Centrifugation: After adding samples and reagents, centrifuge the plate briefly to remove air bubbles and ensure that all liquids are at the bottom of the wells.

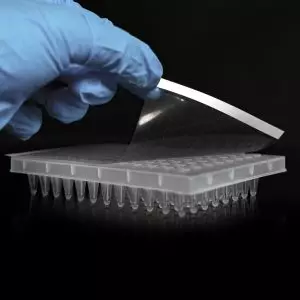

Sealing: Properly seal the plate to prevent evaporation and cross-contamination between wells.

Choosing the Right Sealing Films

Sealing films are critical for protecting samples from evaporation, contamination, and ensuring consistent thermal transfer during PCR. The choice of sealing film depends on the application and the type of microplate used.

Sealing films are critical for protecting samples from evaporation, contamination, and ensuring consistent thermal transfer during PCR. The choice of sealing film depends on the application and the type of microplate used.

Types of Sealing Films

Adhesive Seals: These are pressure-sensitive and suitable for standard PCR. They provide a tight seal but can be challenging to remove without leaving residue.

Heat Seals: Applied using a heat sealer, these films offer a robust seal, ideal for long-term storage and high-throughput applications. They require specific equipment for sealing and removal.

Optical Seals: Designed for qPCR, these seals are transparent to allow fluorescence detection. They minimize interference with optical signals and are typically adhesive-based for ease of use.

Pierceable Seals: These allow easy access to samples with pipette tips or robotic probes without compromising the seal’s integrity. They are often used in automated systems.

Best Practices for Using Sealing Films

Compatibility: Ensure that the sealing film is compatible with your microplate and the thermal cycler. The seal should withstand the temperatures and cycles of your PCR program.

Compatibility: Ensure that the sealing film is compatible with your microplate and the thermal cycler. The seal should withstand the temperatures and cycles of your PCR program.

Application: Apply the seal evenly across the plate to avoid air bubbles. Use a roller or applicator tool to press down firmly, ensuring a uniform seal.

Removal: When removing adhesive seals, peel slowly at a steep angle to minimize residue and avoid dislodging samples. For heat seals, use the appropriate removal tool to avoid damaging the plate.

Storage: If the sealed plates need to be stored, ensure they are kept at the recommended temperature and conditions to maintain the integrity of the seal.

Troubleshooting Common Issues

Even with the best practices, issues can arise in PCR and qPCR experiments. Here are some common problems related to microplates and sealing films, along with troubleshooting tips:

Evaporation: If you notice significant evaporation, ensure that the sealing film is correctly applied. Check for compatibility with the microplate and consider using heat seals for more robust sealing.

Contamination: Cross-contamination between wells can occur if the seal is not tight enough. Ensure even application of the seal and use a new sealing film for each experiment to avoid residual contamination.

Inconsistent Results: Variability in results can stem from inconsistent sample volumes or uneven thermal transfer. Double-check pipetting accuracy and ensure the microplate is correctly positioned in the thermal cycler.

Air Bubbles: Air bubbles can interfere with fluorescence readings in qPCR. Centrifuge the plate after adding samples to remove bubbles and ensure a flat, even surface before applying the sealing film.

Conclusion

In qPCR and PCR experiments, the meticulous selection and handling of microplates and sealing films are integral to achieving high-quality, reproducible results. By understanding the different types of microplates and seals available and adhering to best practices for their use, researchers can minimize errors, prevent contamination, and ensure the integrity of their data.

In qPCR and PCR experiments, the meticulous selection and handling of microplates and sealing films are integral to achieving high-quality, reproducible results. By understanding the different types of microplates and seals available and adhering to best practices for their use, researchers can minimize errors, prevent contamination, and ensure the integrity of their data.

Adopting these best practices not only enhances the reliability of your experiments but also contributes to the efficiency and success of your molecular biology workflows. The right microplates and sealing films can make all the difference in your PCR and qPCR outcomes, hence explore the extensive range of Microlit’s sub brand – Plasticus, By Microlit at www.plasticus.com or email us at info@plasticus.com for any query/information.