How does an autoclave work for Lab instruments?

- May 23, 2023

- ENQUIRE NOW

What is an autoclave?

An autoclave is a machine used to carry out industrial and scientific processes requiring elevated temperature and pressure in relation to ambient pressure and/or temperature. Autoclaves are used before surgical procedures to perform sterilization and in the chemical industry to cure coatings and vulcanize rubber and for hydrothermal synthesis. Industrial autoclaves are used in industrial applications, especially in the manufacturing of composites.

Many autoclaves are used to sterilize equipment and supplies by subjecting them to pressurized saturated steam at 121 °C (250 °F) for around 30-60 minutes at a pressure of 15 psi depending on the size of the load and the contents. The autoclave was invented by Charles Chamberland in 1879, although a precursor known as the steam digester was created by Denis Papin in 1679. The name comes from Greek auto-, ultimately meaning self, and Latin clavis meaning key, thus a self-locking device.

Many autoclaves are used to sterilize equipment and supplies by subjecting them to pressurized saturated steam at 121 °C (250 °F) for around 30-60 minutes at a pressure of 15 psi depending on the size of the load and the contents. The autoclave was invented by Charles Chamberland in 1879, although a precursor known as the steam digester was created by Denis Papin in 1679. The name comes from Greek auto-, ultimately meaning self, and Latin clavis meaning key, thus a self-locking device.

Why Steam?

In order to kill a cell with heat, its temperature must be raised to a degree at which the proteins in the cell wall break down and coagulate. Steam is a very efficient medium for heat transference, which makes it an excellent way to destroy microbes. Air, on the other hand, is a very inefficient way to transfer heat/energy because of a concept known as the heat of vaporization.

The energy is what makes steam so much more efficient at destroying microorganisms. When steam encounters a cooler object, it condenses into water. Then, it transfers all of the energy that was used to boil the water directly into the water. This process heats up the cells far more efficiently than air at similar temperatures. This is why we use steam to achieve sterility.

What is Sterility?

Most people have a working understanding that sterile goods are free of microorganisms and are, therefore, safe to use in medical, food production, research or other settings in which the presence of germs would be a significant safety hazard or detriment.

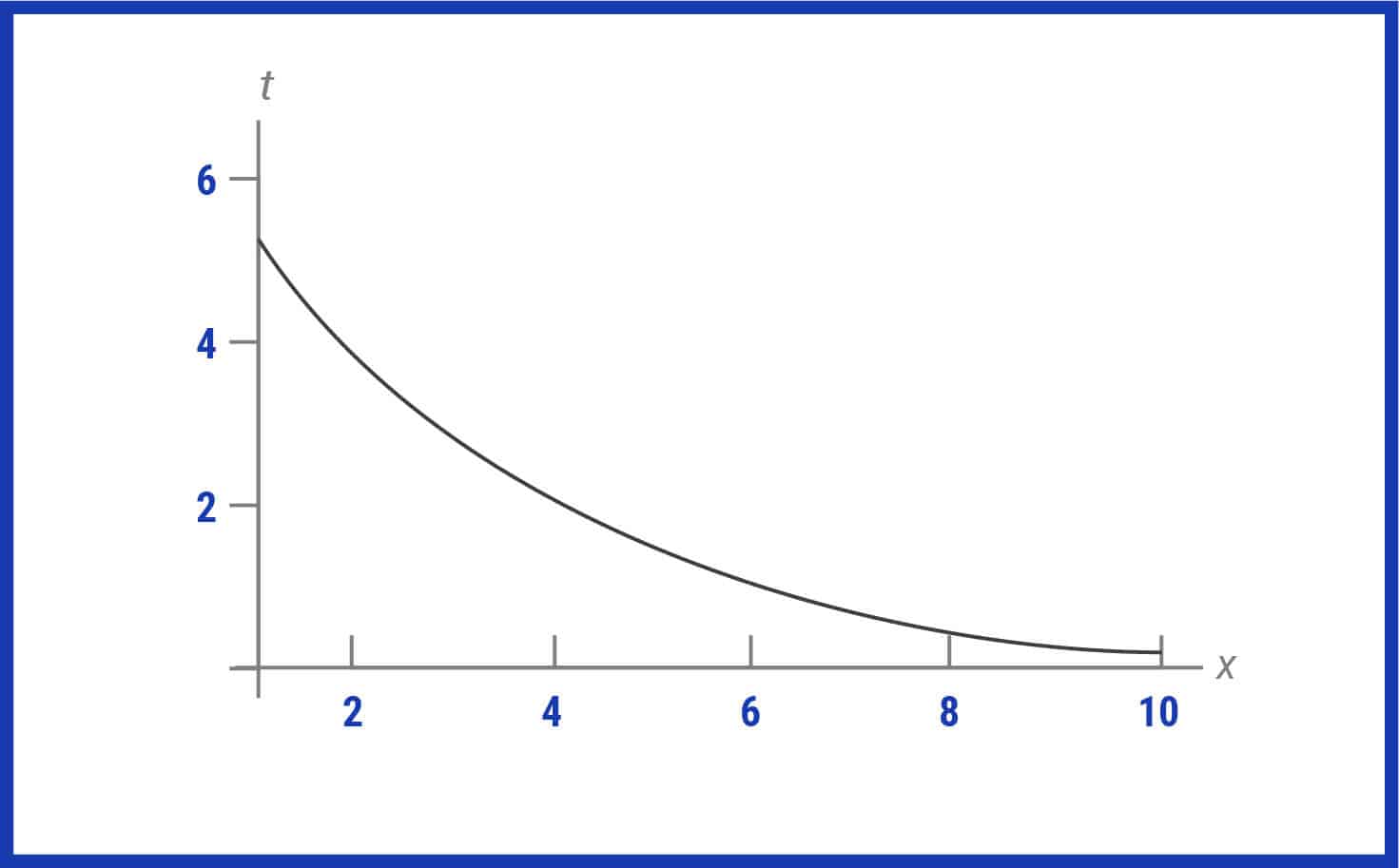

Exactly how many microorganisms will be left alive over time at a fixed temperature is expressed as a probabilistic logarithmic curve — a function that approaches but never reaches zero (see Figure 1).

Types of Autoclaves

Tabletop autoclaves, roughly the size of a microwave oven, are often used in dental offices or small, private medical practices, while larger, horizontal autoclaves are frequently utilized in hospitals in order to handle larger volumes of equipment. Other autoclaves designed for use within the pharmaceutical industry function particularly with current Good Manufacturing Practices (GMP) regulations in mind.

How does an autoclave work?

General Process

Whether it’s a small tabletop unit or a room-sized bulk unit, all autoclaves operate using principles similar to those of a common kitchen pressure cooker — that is, the door is locked to form a sealed chamber and all air within that chamber is replaced by steam. The steam is then pressurized in order to bring it to the desired sterilization for the desired duration. Once the cycle is complete, the steam is exhausted and goods can be removed.

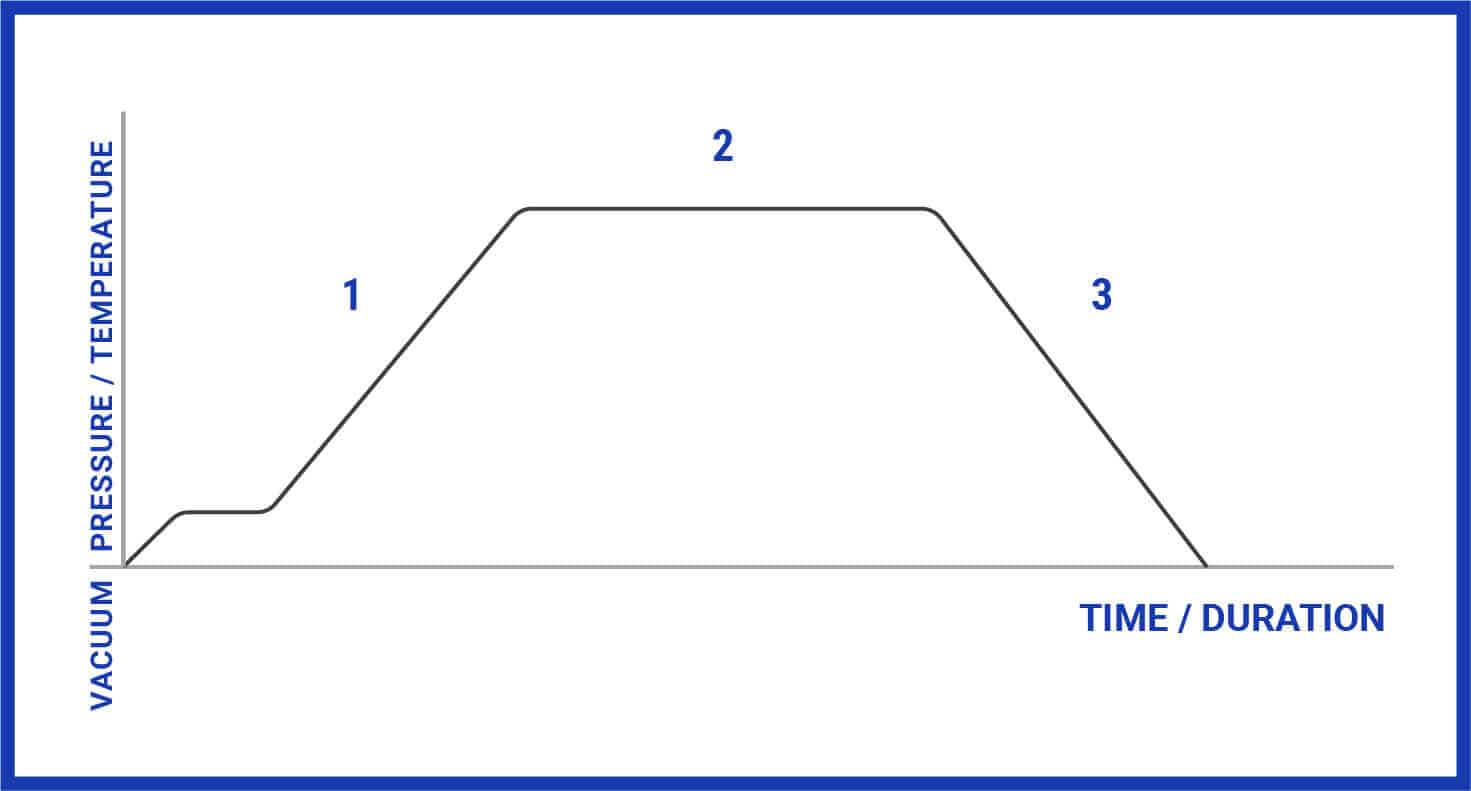

For a more detailed explanation of the various phases of a sterilization cycle, please refer to the list and image (Figure 2):

1. Purge Phase: Steam flows through the sterilizer and starts to displace the air; temperature and pressure ramp slightly to a continuous flow purge.

2. Exposure (Sterilization) Phase: During this phase, the autoclave’s control system is programmed to close the exhaust valve, thereby causing the interior temperature and pressure to increase to the desired setpoint. The program then maintains the desired temperature (dwells) until the desired time is reached.

3. Exhaust Phase: Pressure is released from the chamber through an exhaust valve and the interior is restored to an ambient pressure (though contents remain relatively hot).

Emerging Autoclave Trends

Autoclaves may be considered ancient devices by the standards of modern science, but this does not mean that autoclaves lack innovation, especially when it comes to controls, cloud connectivity and ecological impact.

As mentioned earlier, autoclave controls have advanced greatly in the age of computers, progressing from manual controls and simple timers to computer automation that minimizes or eliminates entirely the need for user input. Computerized controls have also led to advances in data control, record keeping, and remote monitoring via mobile devices. Autoclaves with automatic printers that record data for the purpose of verifying successful sterilization have now been replaced by new autoclaves that connect to the cloud to store cycle records on the internet.

Another trend in autoclave design is sustainability. Autoclaves are a major source of water and energy consumption, both in laboratories and hospitals. In recognition of this, many manufacturers have found innovative ways to reduce autoclaves’ environmental impact. Green autoclaves that reduce or even fully recycle the water consumed by a sterilizer — in some cases, from 1,500 gallons a day to less than one gallon a day — are critical to creating an environmentally friendly laboratory. Control systems that automatically turn the autoclave when not in use can also significantly reduce energy use — in some cases, from 80 kilowatt-hours per day to 20 kilowatt-hours per day.

For further information, drop an email at info@microlit.com and our team will revert ASAP.