Difference between a regular Bottle Top Dispenser & HF Dispenser

- January 23, 2023

- ENQUIRE NOW

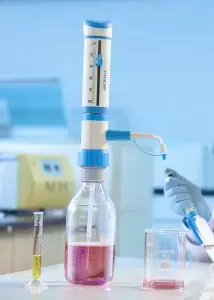

What is a regular Bottle Top Dispenser?

Bottle Top Dispenser is crucial liquid handling equipment used by researchers and scientists in laboratories. It can measure solvents, chemicals, reagents, oil, and so on from several containers, which otherwise becomes a tedious and impractical task. So, to multiply lab safety and prevent any hazardous activities, the Bottle Top Dispenser is vital for carrying out tasks easily and precisely without harming the laboratory environment. Besides ensuring safety in the laboratory, the bottle top dispensers can be used to facilitate a broad range of applications and boost reliability. While working in labs, professionals take appropriate measures to conduct experiments, ensuring safety, especially while working with hazardous chemicals.

Types of Bottle Top Dispensers

Bottle top dispensers can be classified depending upon:

1. Piston Mechanism

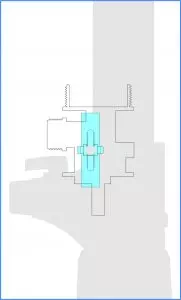

Bottle top dispenser with floating piston

This type of bottle top dispenser does not require any piston seal which makes it very durable and maintenance-friendly. The piston fits into the dispensing cylinder without contact with any surface. The piston and cylinder are separated by a slight gap (around 1 millimetre) which is filled with liquid. This slight film of liquid acts as a lubricant for the piston which helps it to glide very easily while dispensing.

Bottle Top Dispenser with wiping-seal piston

This type of bottle top dispenser comes with a wiping-seal in addition to the floating piston mechanism. Due to this, the system requires a higher operating force during liquid delivery which can lead to faulty sealing due to friction wear.

2. Chemical compatibility of the instrument

Bottle top dispenser for highly corrosive acids

The traditional bottle top dispensers with glass barrels cannot be used to dispense highly corrosive chemicals like Hydrofluoric Acid (HF) and other high-purity media as these may erode the inner surface of the equipment, forming cracks and leading to serious accidents. Thus, a high precision liquid handling instrument engineered with carefully selected and tested materials for use with Hydrofluoric Acid (HF) should be used in this case. The components of the liquid path are carefully chosen so that they do not react/get corroded while getting in contact with the highly corrosive acids. Microlit LENTUS® is one such liquid handling instrument.

Bottle top dispenser for acids, bases and solvents

These bottle top dispensers have a glass barrel, PFA coated or PTFE piston which makes the dispensers compatible with most of acids, bases and solvents. Such dispensers have two valves with glass balls.

Inlet Valve: This valve is vertical. It operates under gravity and does not require a spring to hold the glass ball in its position, in order to keep the valve closed.

Outlet Valve: This valve is horizontal. It requires a spring to keep the glass ball in its position, in order to keep the valve closed while aspirating reagents in the barrel. It opens only when a reagent is being dispensed. The spring housed in the outlet valve, poses problems of spring metal reactivity and chemical deposition.

Hence, Microlit dispensers break the norm by having both inlet and outlet valves in the vertical position. This enables us to eliminate the spring from the valve system as no force is required to keep the ball in its default state.

What is LENTUS® Bottle Top Dispenser?

A high-precision liquid handling tool, the Microlit LENTUS® is engineered with perfection to be used with highly corrosive acids like Hydrofluoric acid, Nitric acid, Sulfuric acid and many others. This Bottle Top Dispenser is mainly used for handling and dispensing high-purity media along with acids and bases. While conducting experiments, the LENTUS® Bottle Top Dispenser exhibits top-notch chemical compatibility and gives accurate results. Not just hydrofluoric acid, it works well with other chemicals and reagents to achieve precision while taking care of safety in real laboratory environments. It is readily available in five unique volume ranges.

A high-precision liquid handling tool, the Microlit LENTUS® is engineered with perfection to be used with highly corrosive acids like Hydrofluoric acid, Nitric acid, Sulfuric acid and many others. This Bottle Top Dispenser is mainly used for handling and dispensing high-purity media along with acids and bases. While conducting experiments, the LENTUS® Bottle Top Dispenser exhibits top-notch chemical compatibility and gives accurate results. Not just hydrofluoric acid, it works well with other chemicals and reagents to achieve precision while taking care of safety in real laboratory environments. It is readily available in five unique volume ranges.

It is incorporated with Springless Valve® and Recirculation Valve technology. This is an ideal choice that prevents the loss of chemicals or reagents while performing experiments. It helps in achieving accuracy with reliability in labs. It is an advanced liquid handling tool that is an ultimate blend of sophisticated features and functionalities.

This Hydrofluoric acid or LENTUS® Bottle Top Dispenser promotes jam-free functioning. It comes with two product innovations, EasyKnob® and FlexiNozzle®, contributing to flexibility and ease of use. When high-purity materials are dispensed using this dispenser after appropriate cleaning, they release virtually no metal ions. This makes the dispenser suitable for trace analysis.

Features of LENTUS® Bottle Top Dispenser

While handling harsh chemicals like Hydrofluoric acids, nitric acid, sulfuric acid, hydrochloric acid, LENTUS® Bottle Top Dispenser can be used to facilitate a wide range of actions.

Chemical Compatibility

The Microlit team has developed innovative equipment to ensure the easy and safe handling of corrosive reagents. The traditional Bottle Top Dispensers were not able to dispense corrosive liquids effectively. They tend to erode, form cracks or even lead to significant accidents. As a result, a better version came into play. Microlit LENTUS® is an improved version of the existing dispenser design. It is a Bottle Top Dispenser composed of tested materials to ensure the accurate dispensing of corrosive chemicals in the requisite quantity.

Change Volume with EasyKnob®

Change Volume with EasyKnob®

LENTUS® Bottle Top Dispenser features the newest technology, EasyKnob®. It allows easy 180° rotation for effortless volume setting.

Move effortlessly with a PTFE Piston

This Bottle Top Dispenser features a PTFE Piston along with the ETP O-Ring. It ensures effortless and smooth movement. It also makes sure of high chemical compatibility.

Re-direct Liquids with Recirculation Valve

The recirculation valve present in the LENTUS® Bottle Top Dispenser prevents any loss of reagents when purging takes place by re-directing it into the mounted bottle. It also facilitates no-bubble dispensing.

Operate Jam-free with Springless Valve®

It features an award-winning technology called Springless Valve® which ensures easy and jam-less movements.

Dispense Easily with FlexiNozzle®

It comes with another promising technology, FlexiNozzle®, an adjustable nozzle ensures easy flexibility and facilitates easy and smooth dispensing at various dispensing angles.

Work Flexibly with a 360° Adapter.

The adapter allows 360° rotation ensuring complete flexibility and easy movements.

Assured Quality with ISO 8655 Conformed Calibration

According to ISO 8655 standards, this dispenser is calibrated in an ISO 17025 accredited laboratory. In the product package, a calibration certificate is also included.

Work with a Comprehensive Volume Range

This Bottle Top Dispenser is primarily available in five broad volume ranges.

Major difference between a regular Bottle Top Dispenser and HF Dispenser

1. Chemical Compatibility – A regular Bottle Top Dispenser can dispense different types of reagents like organics, inorganics, solvents etc. However, Microlit LENTUS® is engineered with perfection to be used with highly corrosive acids like Hydrofluoric acid and high-purity media along with acids and bases. LENTUS® is a Universal Dispenser for all reagents – acids, organics, inorganics, solvents including HF. While conducting experiments, the LENTUS® Bottle Top Dispenser exhibits top-notch chemical compatibility and gives accurate results.

2.  Material of Construction (MOC) – A regular bottle top dispenser is generally equipped with a glass barrel, PFA coated or PTFE piston which makes the dispensers compatible with most of the acids, bases and solvents and facilitates smooth and effortless movement. The materials used in LENTUS® Bottle Top Dispenser ensure that it is not affected by direct contact with corrosive acids and does not allow the introduction of trace elements in the dispensed liquid. For use with HF, Microlit R&D team tested numerous materials including ceramics, glass, FEP etc. for different components including barrel, valve system and delivery tube. LENTUS® Bottle Top Dispenser has no glass components inside it, and the material of wetted internal parts include PTFE, FEP and Alumina Ceramic (Chemical formula – AL2O3).

Material of Construction (MOC) – A regular bottle top dispenser is generally equipped with a glass barrel, PFA coated or PTFE piston which makes the dispensers compatible with most of the acids, bases and solvents and facilitates smooth and effortless movement. The materials used in LENTUS® Bottle Top Dispenser ensure that it is not affected by direct contact with corrosive acids and does not allow the introduction of trace elements in the dispensed liquid. For use with HF, Microlit R&D team tested numerous materials including ceramics, glass, FEP etc. for different components including barrel, valve system and delivery tube. LENTUS® Bottle Top Dispenser has no glass components inside it, and the material of wetted internal parts include PTFE, FEP and Alumina Ceramic (Chemical formula – AL2O3).

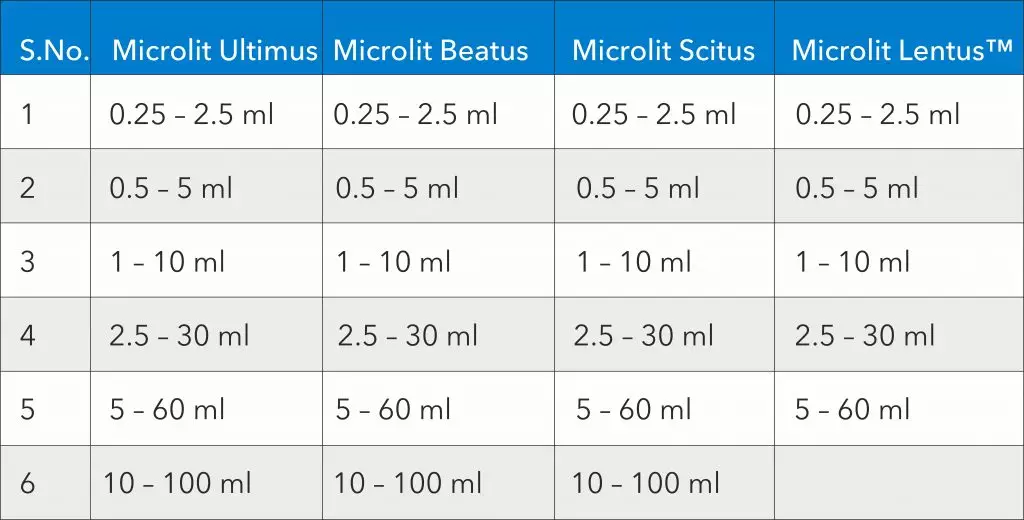

3. Volume Range – A regular Bottle Top dispenser is generally available in different volumes ranging from 0.25ml to 100ml. However, LENTUS® bottle top dispenser is available in 5 unique volume ranges upto 60ml. Ref below chart of all Microlit’s Bottle Top Dispensers with various volume ranges. Users can choose as per the requirement of their Lab.

4. Price – The LENTUS® bottle top dispenser is budget-friendly as compared to other international brands as expensive inert materials are used for the barrel and valve system like Fluoropolymers and high-purity ceramics to dispense highly corrosive chemicals and acids.

5. Color of Product – The LENTUS® bottle top dispenser has unique grey-colored components that act as standouts compared to a regular bottle top dispenser with orange or blue colored components.

Various Industries where LENTUS® Bottle Top Dispensers are used:

This Bottle Top Dispensers find widespread use in various industries. Mainly, in processes where corrosive or hazardous fluids need to be transferred seamlessly without posing any exposure hazard to the individuals handling them. At the same time, they make sure to maintain volume accuracy. Moreover, the this Bottle Top Dispenser is of significant value in the pharmaceutical, research, and development industries to conduct qualitative and quantitative assessments. The industry’s strict quality maintenance and protocol requirements make it imperative. It is where this product provides the most value and acts as the next major upgrade in the field.

• Glass industry

• Oil and Gas

• Polymer manufacturing

• Earth sciences (Geology)

• Pharmaceutical

• Metal Pickling

• Uranium / Atomic Energy

• Pesticides and fertilizers

• Environmental Testing

• Food & Beverage Testing

• Semiconductor Testing

• Clinical Diagnostics

• Mining

• Cosmetics

• Chemicals manufacturing

• Consumer products (FMCG)

How to Choose the Right Bottle Top Dispenser?

Generally choosing a Bottle Top Dispenser depends on the amount of liquid and its types. However, other factors must be considered when choosing the right Bottle Top Dispenser for the laboratory.

Chemical compatibility – When selecting a Bottle Top Dispenser, the user should check the chemical compatibility of the dispenser with the reagent to be dispensed. Some manufacturers offer different Bottle Top Dispenser models for different types of reagents – organics, inorganics, solvents etc. All manufacturers offer a chemical compatibility chart with their dispensers. This includes all the commonly used reagents and their compatibility with the materials used in the construction of the dispenser. Please be sure to check compatibility chart before making a purchase.

The commonly used reagents with Bottle Top Dispensers can be categorized as follows:

The commonly used reagents with Bottle Top Dispensers can be categorized as follows:

Acids: Examples include Acetic Acid, Hydrochloric Acid, Sulfuric Acid, and Nitric acid

Bases: Examples include Acetyl chloride, Ammonia, Pyridine and sodium hydroxide

Organic Reagents: Examples include Toluene, Methanol, Trichloro trifluoroethane and Dichloromethane.

Highly Corrosive Acids: Hydrofluoric Acid – LENTUS® bottle top dispenser is suggested.

Viscosity of the reagent – If you need do dispense viscous liquids such as Essential Oils, Botanical Extracts, Grain Alcohol and Vegetable Glycerine, the applicable viscosity range for the dispenser needs to be considered. Highly viscous liquids with a kinematic viscosity of between 75 to 500 mm2/second will require careful selection while reagents having kinematic viscosity below 75 mm2/second can be used with any kind of bottle top dispenser efficiently.

Capacity of the dispenser – Bottle Top Dispenser comes in both fixed volume and adjustable volume models with a specific range of liquid quantity. The volume can be adjusted either manually with the help of a knob or dialled electronically through a control panel. So, it is necessary to make sure that your selected Bottle Top Dispensers are able to dispense the amount of liquid that is frequently required for your experiments. Note that dispensers with lower capacities offer higher accuracy and precision. So, if you want to dispense 10ml, a 1-10ml dispenser is recommended over a 2.5-30 ml dispenser to ensure more accurate results.

To know more about whole range of Microlit’s bottle top dispensers, visit our website link: https://www.microlit.com/product-category/bottle-top-dispensers/ or email us at info@microlit.com for any query/demo/information.